LIFTING BODIES

One of the

reasons for the delay in completing this model

was that I was unsure of how to construct the

large wings; I was also worried that after

building them they would both end up drooping!

My basic technical knowledge told me that several

layers of materials glued together, in a

composite, are stronger than one thick material

as they act against each other. So I decided to

build up the shape of each wing using layers of

different materials starting with the basic

outline cut from thin MDF.

This MDF sheet

became the horizontal centre of the wing with

sheets of Balsa added above and below to create

the aerofoil shape. As the wing thickness also

reduces towards the wing tip I glued plastic

tapering strips into place behind the leading

edge in order to act as guide markers for sanding

down the Balsa to the desired angles. Weights

were placed on the sheets of wood to keep them

compressed while the glue set, after which I

could then begin shaping the wings by firstly

trimming off the obvious surplus wood with a

knife. The pictures here show the front wing

which was easier to work on as both wingtips were

made separately. Later in the process I removed

the rear protruding engine area and the two front

inlets..

The next stage

was to spend a great deal of time sanding the

wings down to the correct shape - and then to

take them down even further, as the wood needed

to be given a fibreglass coating which would add

to the overall thickness.

When they were ready I gave the wings a coat of

SP113 laminating resin, this is a two-part epoxy

resin (used by radio controlled model aircraft

and boat builders) that depending on the mixture

and temperature takes up to a day or more to set

properly. This initial coating sinks into the

wood and when set leaves a rough surface finish

that needs cutting back with wet & dry

abrasive paper. I then checked over the wing for

any major imperfections that needed correcting

with car filler before applying another coating

of the resin. This next application also included

fibreglass tissue, to give the wings extra

strength, and it had to be applied very carefully

to prevent any lumps appearing. Again it was all

left for several days to thoroughly set before

being sanded down and a final topcoat of resin to

finish it all off. Then the wings were then

treated with several coats of spray filler and

sanding began again with any uneven areas and

holes being fixed with car filler..

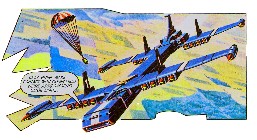

Picture right;

shows the rear wing, with the areas for the

undercarriage being cut out. There isn't really

enough room in the wing for the wheels to fit but

I preferred to cut a semi-recess than just fix

the undercarriage to the wing surface (which is

often seen on models that appeared in Gerry

Anderson TV shows).

A master pattern

for the bullet shaped front end was sculpted,

moulded in plaster and then two copies cast up in

a resin/car filler mix. These were then secured

to the MDF core of each wing, with the

surrounding air-intake areas formed in plastic

sheeting which was all blended into the wing with

more filler..The rear triangular engine sections were

made in a mixture of plastic and filler.

For the outer

wing fairings I made a master pattern of only

half the shape then cast up eight copies and

paired them off.

See the Thunderbird

3 build for

details on making this type of shape.

The areas for

the undercarriage hatch covers were pencilled

into position and drilled out. Slots were also

drilled out to allow the fairings to be embedded

onto the wingtips, superglue held them in

position whilst car filler was smeared around the

parts to securely lock everything together..

The vertical

fins on the wings were formed from MDF. A centre

line was drawn around the edges of each fin and

then they were sanded down to an aerofoil shape,

coated in resin and sanded smooth. Cardboard

versions were used to test the final shape and

position. The fins are one of the items that are

very different on the two studio models.

Slots were cut into both the fins and wings

allowing them the lock into each other. Then the

parts were glued and filler used to blend them

together..

The next problem

was building 16 engines!

Repetitive jobs are something that I hate doing,

as I'm usually very bored by the time I've made

the fifth identical part! Although the engines

look like square boxy shapes they do have very

round edges so making them from plastic sheeting

would not only require a lot of pieces but then a

lot of hard sanding.

The answer, again, was to cast the parts in a car

filler/resin mixture using some sort of mould.

For speed I

decided against making a rubber mould and opted

for a solid plastic one that could be taken apart

to release the castings. Here a centre core forms

the main shape with the sides, strengthened with

metal rods, simply held in place with elastic

bands.

As the mixture dissolves styrene plastic I had to

cover the parts in adhesive metal foil that I

waxed to help prevent the filler from adhering.

The aerofoil

shape of the wing was cut from the sides of each

engine using two templates as a rough quick

guide. Then each engine was carefully adjusted to

its correct position and numbered so I didn't mix

them up. To create a perfect join a small amount

of filler was applied to each edge and then the

engine bodies were pushed into place against the

wings surface.

The surplus filler that squeezed out of the sides

was trimmed off as it began to set, whilst the

wings paint surface was protected during the

process by temporarily covering it with clear

adhesive tape. Note - The tape is first applied to

either my skin or trousers to kill off some of

its adhesive strength and stop it from lifting

the paint when it is removed. .

Because of the

tape all 16 engine bodies could then be easily

prised off, sanded smooth, painted, then

reattached using clear 2-part epoxy glue. More

detailed multiple parts had to be produced using

rubber moulds. These were all painted prior to

being fixed in position.

There are no

reference photos of the inside of the wheel

housings so I just had to invent something that

looked good. The hatch covers were vac-formed in

0.75mm plastic sheet over the master pattern.

The large inlet cones were temporarily glued into

position whilst the series of small plastic vanes

were applied around the base, each one having to

be trimmed to perfectly match the gap, then the

finished part could be snapped free and painted

before being permanently attached.

The large

numbers were spray painted on using masking tape

outlines. Letraset numbers were enlarged to the

right size and used as a guide to cut out the

shape from the masking tape. These numbers were

placed on the model and moved about until they

were in the right position, then the surrounding

tape was placed back over it and the number

removed. The edges of the tape were carefully

pressed down, to stop any paint from bleeding

under it, and then the paint applied in a series

of light coats, again to prevent bleed through

and get a sharp edge..

More sets of

wheels were now assembled. Luckily the front wing

only has two sets but the rear wing features

five, which includes a small steering unit. The

two main centre sets were soldered to Brass

plates that were glued into the wing recesses.

|

![]()